ADAM PROVISIONING S2000M

take control of your supply data

ADAM Provisioning S2000M offers a robust and user-friendly environment to streamline your supply chain activities while ensuring regulatory compliance.

Adam Provisioning S2000M for ensuring parts and services availability in maintenance

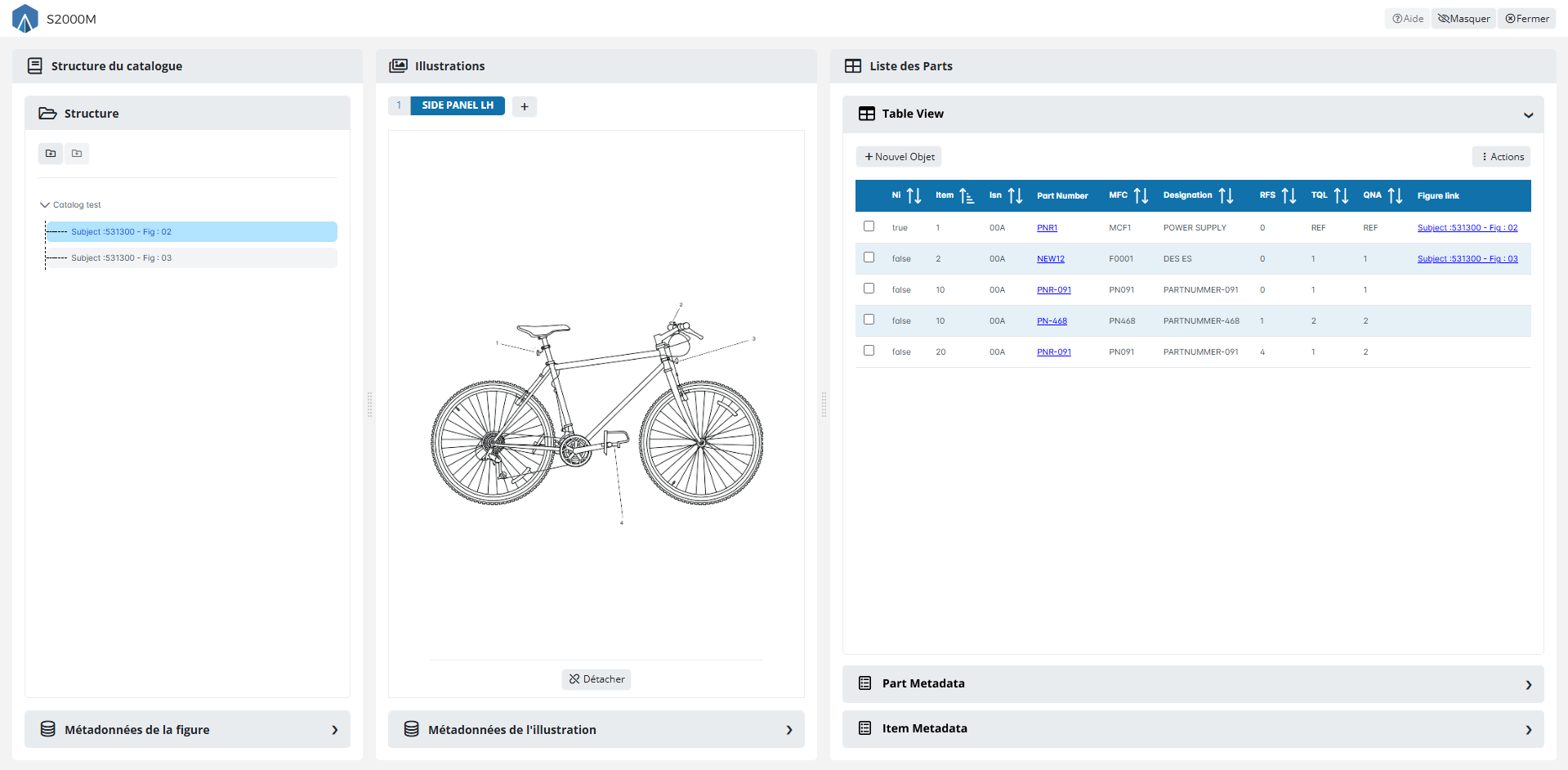

Directly integrated with the ADAM IPC Builder interface, ADAM Provisioning S2000M displays a parts list in a table view within the catalog’s navigation and visualization interface.

ADAM Provisioning S2000M is a comprehensive and intuitive solution designed for managing, producing, and distributing supply data. Built to comply with S2000M chapters 1A and 1B, it seamlessly integrates with business processes, streamlining the creation of required messages and reports.

Whether managing IPPN, CSN, or Part Numbers, ADAM Provisioning S2000M provides a robust and ergonomic environment for optimizing supply chain operations while maintaining full regulatory compliance.

Why choose ADAM Provisioning S2000M?

Compliance with international standards

Ensure that your supply data meets the S2000M standard, guaranteeing high-quality deliverables and standardized exchanges with partners.

Ease of deployment

With its 3-Tier architecture, ADAM S2000M is simple to implement, even in complex multi-site environments.

Integration with other systems

Easily import and export Part Numbers and CSN data, and integrate codification returns (ACODP1).

Creation of hierarchical catalogs

Create customized catalogs per system or client, with advanced pricing and item management features.

ADAM Provisioning S2000M

is a robust and connected technology

With ADAM S2000M, access a high-performance platform that centralizes logistics data while remaining accessible via a web browser. Thanks to seamless integration with existing logistics databases and advanced data verification features, this solution ensures precise and reliable operations tracking.

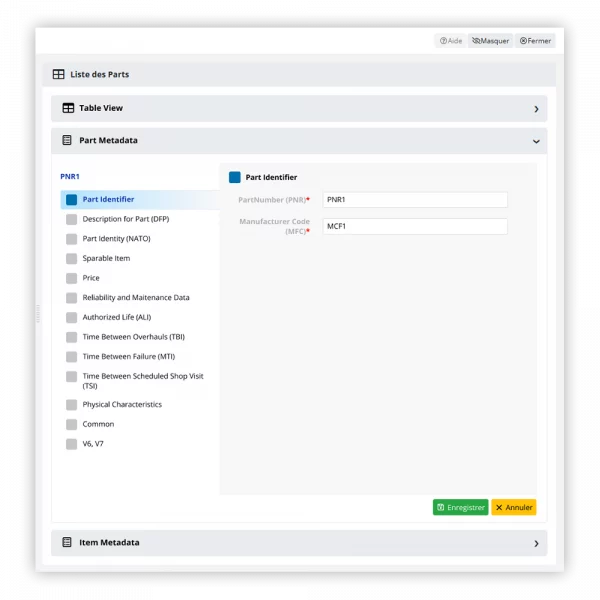

Identification and traceability of parts with ADAM PROVISIONING S2000M

ADAM PROVISIONING S2000M ensures strict management of spare parts by integrating S2000M standards for reliable and standardized identification. By managing the Part Number (PNR) and Manufacturer Code (MFC), each part is assigned a unique number along with its manufacturer, ensuring complete traceability and seamless interoperability with logistics and supply chain systems.

This feature helps prevent identification errors, simplifies exchanges with suppliers, and optimizes stock management. With ADAM PROVISIONING S2000M, you gain full control over your technical database and ensure effective management of parts throughout their lifecycle.

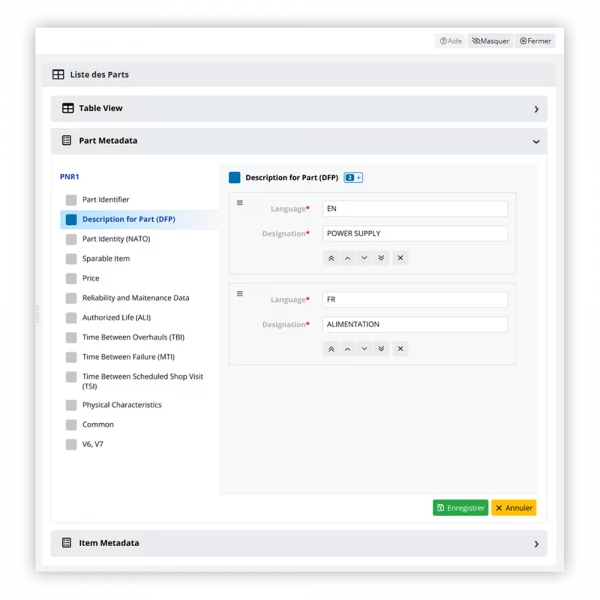

Multilingual part description management with ADAM PROVISIONING S2000M

ADAM PROVISIONING S2000M enables multilingual management of part descriptions, ensuring compliance with the S2000M standard. This guarantees smooth communication among international logistics support stakeholders. Thanks to this feature, each part can be described in multiple languages, facilitating identification and information exchange in a multinational environment.

This approach enhances optimized interoperability between maintenance and supply chain systems, reducing translation errors and improving data consistency. With ADAM PROVISIONING S2000M, streamline your documentation management and enhance collaboration in global projects.

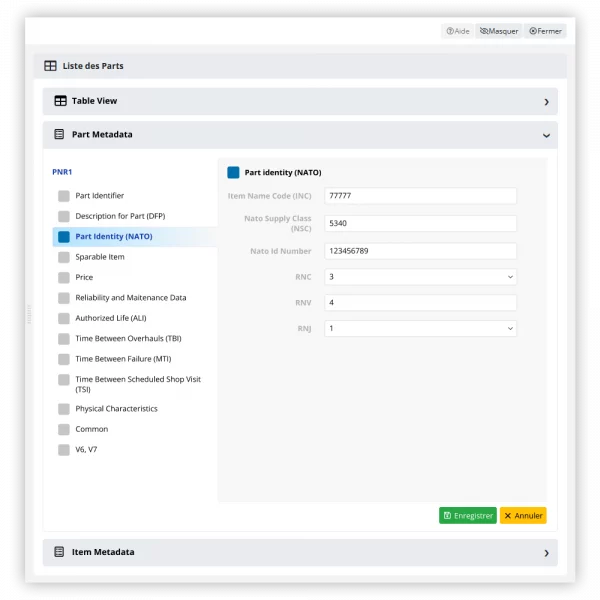

Standardized part identification with ADAM PROVISIONING S2000M (NATO)

ADAM PROVISIONING S2000M ensures compliance with NATO Codification System (NCS) standards for effective management of critical parts and equipment. By integrating NATO codes, including the Item Name Code (INC), NATO Supply Class (NSC), and NATO ID Number, each part benefits from complete and standardized traceability within military and industrial logistics systems.

This feature guarantees seamless interoperability among different logistics support stakeholders and facilitates integration with National Codification Bureaus (NCBs) databases. With ADAM PROVISIONING, you can secure and standardize your component management while complying with strict Integrated Logistics Support (ILS) requirements.

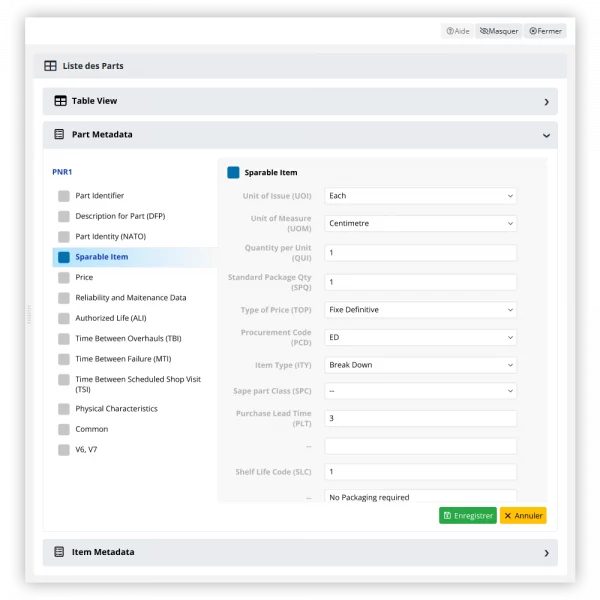

Advanced spare parts management with ADAM PROVISIONING S2000M

ADAM PROVISIONING S2000M simplifies spare parts and supply chain management by integrating S2000M specifications. Thanks to an intuitive interface, users can efficiently manage part metadata, including unique identification, unit measurements, purchasing lead times, and logistics classifications.

This module provides optimized management of replaceable items (Sparable Items) by ensuring precise traceability and data standardization. It facilitates order planning, reduces supply chain delays, and ensures seamless integration with ILS (Integrated Logistics Support) systems.

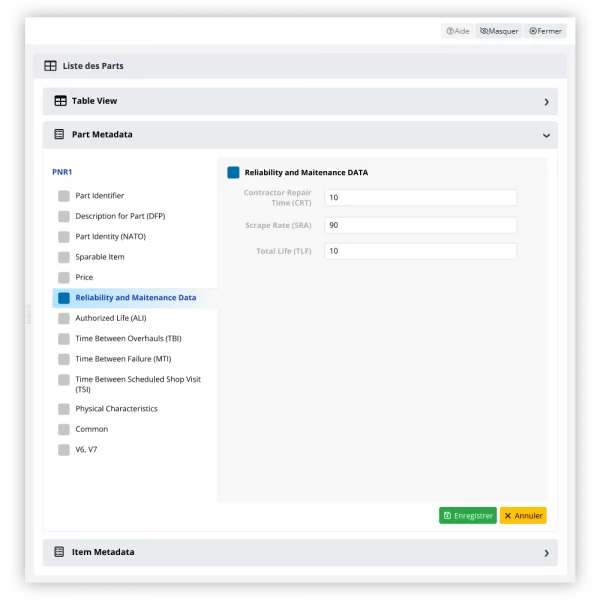

Reliability and maintenance optimization with ADAM PROVISIONING S2000M

ADAM PROVISIONING S2000M streamlines the management of reliability and maintenance data for spare parts in accordance with S2000M standards. This feature ensures precise tracking of Contractor Repair Time (CRT), Scrap Rate (SRA), and Total Life (TLF) of components.

With a clear and intuitive interface, users can anticipate maintenance needs, optimize stock management, and enhance the operational availability of critical equipment.

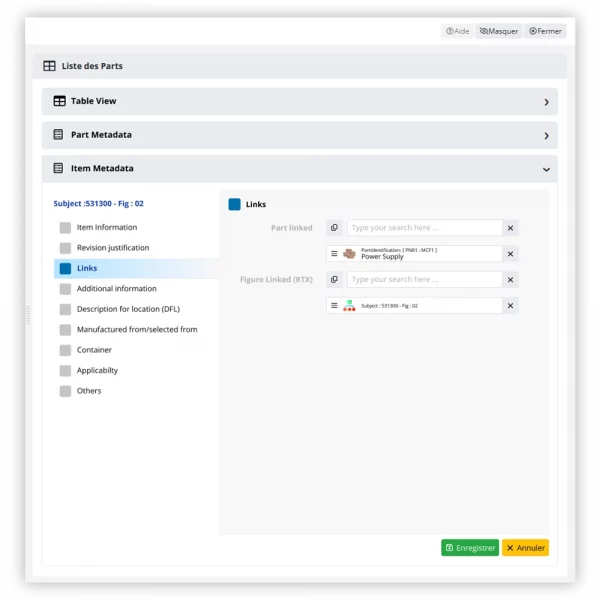

Management of part links and references with ADAM PROVISIONING S2000M

ADAM PROVISIONING S2000M provides advanced component link management following the S2000M standard, ensuring precise traceability of parts and associated documentation. This feature allows users to easily link spare parts (Part Linked) and illustrative figures (RTX – Figure Linked), ensuring clear and consistent documentation.

This approach enhances catalog navigation, streamlines component identification, and improves procurement processes. ADAM PROVISIONING S2000M simplifies part-to-document relationship tracking, guaranteeing optimal interoperability with maintenance and logistics systems.

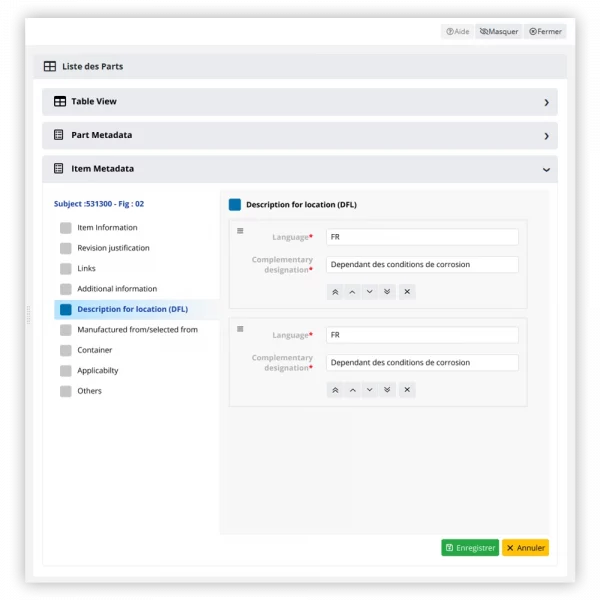

Managing location descriptions with ADAM PROVISIONING S2000M (DFL)

ADAM PROVISIONING S2000M integrates the Description for Location (DFL) feature to precisely document the location and conditions of use of parts and components. This feature allows contextual information, such as environmental constraints (e.g. corrosion, temperature), to be indicated, guaranteeing efficient management of items according to their specific use.

Thanks to multilingual support and an intuitive interface, users can structure and centralize part location information to improve traceability, preventive maintenance and inventory management. With ADAM PROVISIONING S2000M, optimize component identification and operation while complying with S2000M standards.

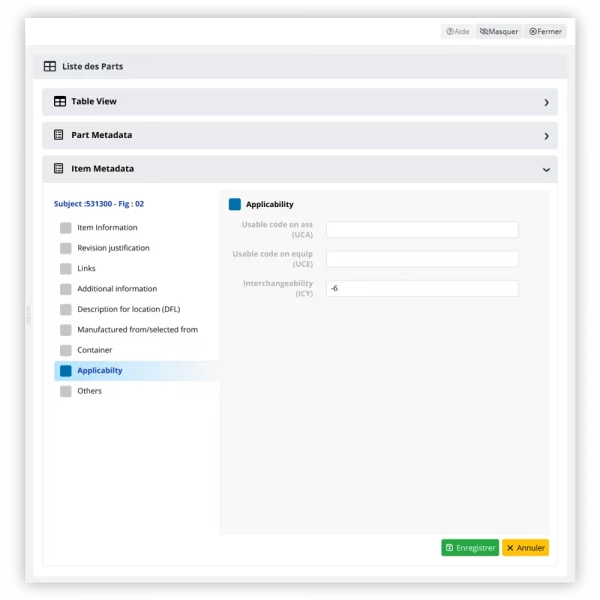

Applicability and interchangeability management with ADAM PROVISIONING S2000M

ADAM PROVISIONING S2000M incorporates advanced functionality for managing the applicability of parts, guaranteeing optimum traceability and compatibility of components with the assemblies and equipment concerned. Thanks to the Usable Code on Assembly (UCA) and Usable Code on Equipment (UCE) fields, each part is clearly identified according to its context of use.

The Interchangeability (ICY) indicator, meanwhile, makes it possible to manage matches between spare parts, facilitating their replacement and logistics management. This approach improves inventory management, reduces procurement errors and optimizes maintenance by guaranteeing interoperability in line with S2000M standards.

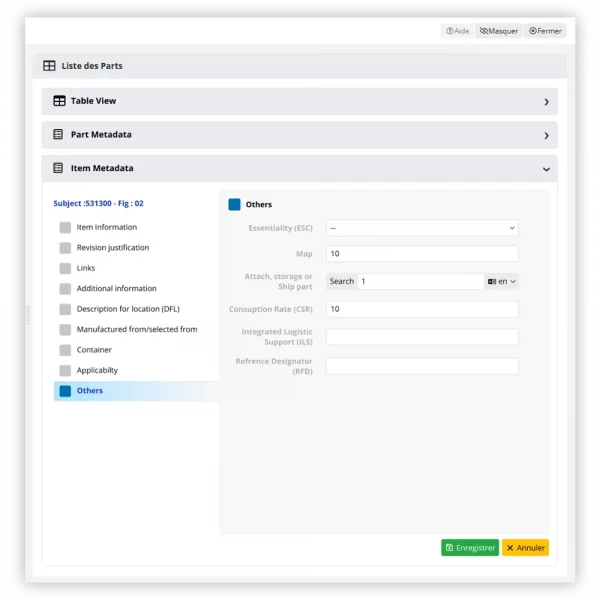

Advanced management of logistical parameters with ADAM PROVISIONING S2000M

ADAM PROVISIONING integrates advanced functionalities for managing logistical and technical parameters of spare parts, in line with S2000M standards. Thanks to fields such as Essentiality (ESC), Consumption Rate (CSR) and Integrated Logistic Support (ILS), users can assess the importance of a part, track its consumption rate and ensure its integration into logistics support processes.

The Attach, Storage or Ship Part option identifies parts requiring specific storage or suitable packaging for transport. Finally, the Reference Designator (RFD) ensures detailed traceability of components in complex systems.

With ADAM PROVISIONING S2000M, optimize your logistics management by centralizing and structuring all critical information linked to parts and components, thus guaranteeing interoperability and full compliance with S2000M standards.

Discover our S2000M solution

Want to learn more? Contact us today

To find out how ADAM Provisioning S2000M can transform your procurement processes, contact our team!

Additional modules and add-ons

ADAM CATALOG

3D software for creating illustrated parts catalogues and managing changes.

ADAM Viewer

An app for viewing technical documentation in S1000D, ATA2300, and PDF formats.

ADAM 3D Plugin

Script your technical documentation using the 3D models of your digital mock-ups.

ADAM Logistics S3000L

Import your S3000L logistic data into your technical documentation projects.

ADAM Data Checker

Validate your data with integrated XML S1000D and ATA SGML validation or via web service.